No Dig Technologies

Pipe Renovation with Cured-in-Place Pipe (CIPP)

During renovation we place a liner that was previously impregnated with resin that cures when treated with higher temperature. As a result of the curing of the resing we get a composite liner that minimally reduces the diameter of the renovated pipe. The capacity of the pipe is not reduced.

You can find more details of this technology on the Agriapipe website.

You can find more details of this technology on the Agriapipe website.

Pipe Renovation with Swage Lining / Sliplining

Before the renovation the liners have to be made continuous, for example, in the case of PE pipe, the parts need to be welded together. The diameter of a pipe prepared like this will be smaller than the diameter of the pipe to be renovated. After pulling in the liner the annular space has to be grouted. The capacity of the renovated pipe decreases.

You can find more details of this technology on the Agriapipe website.

You can find more details of this technology on the Agriapipe website.

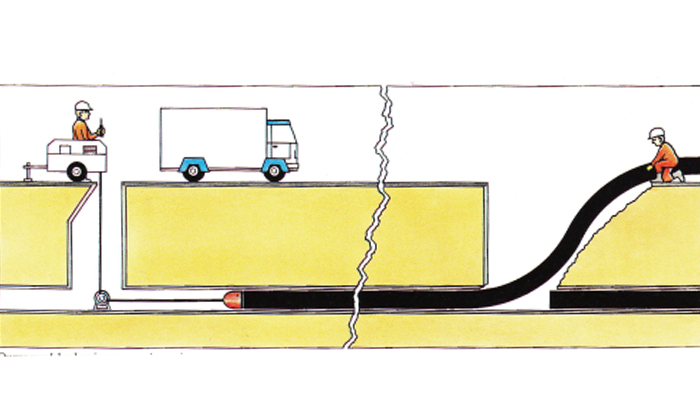

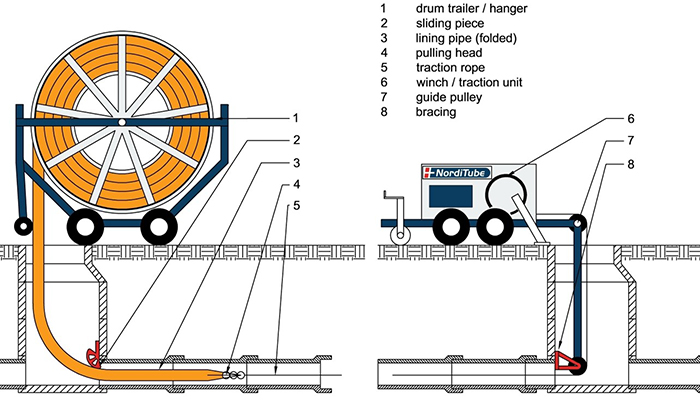

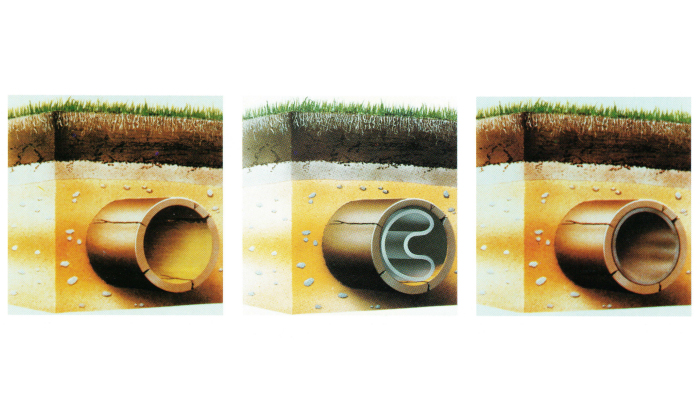

Pipe Renovation with Close-fit (Rolldown, CF-liner)

The diameter, circumference of the liner before renovation has to be reduced either at the jobsite or in the factory. After pulling in the liner the liner gets is previous form back. Therefore the liner is closely fitting to the wall of the original pipe. This resluts in no reduction in the capacity of the pipe.

You can find more details of this technology on the Agriapipe website.

You can find more details of this technology on the Agriapipe website.

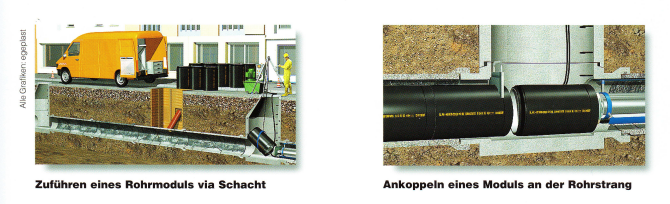

Pipe Renovation with Segmental Lining

During renovation we use a liner that has a smaller diameter than the host pipe. The short liners are connected in the manhole. The connected pipes are either pulled in or pushed in to the host pipe. The annular space between the liner and the host pipe has to be grouted. The capacity of the renovated pipe is reduced.

You can find more details of this technology on the Agriapipe website.

You can find more details of this technology on the Agriapipe website.

Pipe Renovation with Spirally Wound Technologies

For renovation we use a liner wounded at the jobsite from PVC profiles. The spirally wounded liner is then placed into the sewer. The diameter of the liner is expanded until it is closely fitting to the wall of the host pipe. Like this the capacity of the renovated pipe is not affected.

You can find more details of this technology on the Agriapipe website.

You can find more details of this technology on the Agriapipe website.

Pipe Renovation with Digging

Renovation with digging is basically replacing the old pipe with a completely new one. The pipe to be renovated has to be dug out on its whole section and taken out from the ground. The new pipe is built into the place of the old pipe. The old and removed pipes are considered to be hazardous waste, therefore they need special treatment even after renovation too,such as the azbestos cement pipes.